Contradictions: A Tool for Systematic Innovation

The Quest for a Killer App for Identifying Problems and Generating Solutions

Through the first 20 years of my engineering career, I unsuccessfully sought the “killer app” for Systematic Innovation (“SI”). Each time I began employment with a heavy-hitter organization (such as the US Air Force Research Lab, Johnson and Johnson, Philips, and Intel Corp.), I enquired if they had a systematic problem deconstruction and solution generation methodology at the ready to help me join the ranks of the world-class problem solvers who were surely responsible for their standing in the industry. Each time the answer was, “No, but you’ll figure it out, that’s what engineers do”.

After having acquired a lot of problem-solving experience with complex systems, I began to see why it might be difficult to conceive, let alone develop, a general methodology that could help you understand the workings of a complex system (in fields as diverse as microbiology and nuclear engineering), then allow you to systematically develop effective solutions to its problems.

But wait, such problem-solving systems do exist for some fields! We do not have to look further than mathematics, chemistry, statistics, and other such areas. What do such disciplines have in common? They all shift the analysis from the real to the abstract world and then back again during solution generation. Can we not develop a methodology that generalizes the approaches used in such disciplines to allow us to apply it to any type of system?

Good Things Come to Those Who Wait

Having spent 20 years in the industry, I finally discovered that elusive “killer app.” Around ten years into my employment with Intel, a relatively new methodology called TRIZ was introduced into the company. TRIZ (an acronym for the Russian equivalent of “The Theory of Inventive Problem Solving”), is based on a long-running study of over four million patents from the worldwide patents data base. It lets you abstract your specific problem in a manner that allows it to be compared to other, seemingly unrelated, problems. This allows you to explore solutions that have worked for related abstractions and apply those solutions to your own problem. The methodology is both broad and deep, but this article will take a look at Contradiction Analysis, one of the many tools that are part of the TRIZ toolkit. Contradiction Analysis clarifies the root of, and provides tremendous insight into, the problem you are trying to solve.

Contradiction Analysis

Contradictions were first explored in a dialogue by Plato written in 384 BC. His pupil Aristotle’s law of non-contradiction says that “One cannot say of something that it is and that it is not in the same respect and at the same time”. Clearly, the concept of contradictions is not unique to TRIZ, but the application to engineering problems and the specific formulations of those abstractions is.

In TRIZ there are two forms of contradiction statements. The form that represents the highest level of abstraction, and therefore provides the clearest view of the root problem to be solved, is called a physical (or inherent) contradiction. Capturing a physical (or inherent) contradiction is simple but does required adherence to a particular formulation. That formulation is as follows:

Want a specific situation for the purpose of a specific benefit

-and-

Want the opposite of the original specific situation for the purpose of a different specific benefit.

Some examples are:

- Want a large automobile engine for the purpose of high power AND Want a small engine for the purpose of high gas mileage.

- Want a power cord for the electric lawnmower for the purpose of providing electricity to the machine AND Want no power cord for the electric lawnmower for the purpose of increasing the mobility of the machine.

- Want high temperature water in the clothes washer for the purpose of loosening and dissolving grease AND Want low temperature water in the clothes washer for the purpose of not damaging the clothing.

It turns out that to innovate, one must transcend a limiting situation. Stating the contradictions that characterize the design of a system, or its sub-components, helps us visualize the system’s limiting factors as well as the ways to get around them.

Contradiction Analysis in Action

As far as the automobile engine size is concerned, auto manufacturers only recently started resolving the contradictory requirements of high power versus high gas mileage. Before that, they simply created different designs for different applications, e.g., large engines for sports cars and trucks (high power and low gas mileage) and small engines for sub-compacts (low power and high gas mileage).

The physical (inherent) contradiction statement around the size of the automobile engine clearly shows that we want both a large and small engine at the same time and what the benefits of those opposites are. Within the past few decades, the auto industry has indeed introduced design changes that begin to resolve the contradictory requirements around the size of the engines utilized. For example, in 1979 GM introduced the V8-6-4 engine which deactivated and reactivated cylinders based on instantaneous power needs, thus increasing the overall gas mileage. Hybrid engine vehicles accomplish the same by using a small gas powered engine (higher gas mileage) combined with an electric motor (higher power). And, as of late, auto manufactures are more often turbo-charging small gasoline engines providing higher power when needed but allowing high gas mileage for the reminder of the drive time.

In relation to the electric lawnmower power cord versus no power cord contradiction, the advancement of lithium-ion batteries has allowed battery powered electric lawnmowers to have sufficient power and run time to allow the loss of the traditional extension cord. In the not too distant future, the equipment that is now powered by batteries may be instead powered by wirelessly beamed electricity.

While I have not yet seen clothes washing machines that address the contradictory requirements around the water temperature used during the washing cycle, stating the contradictory requirements (i.e., hot water to loosen and dissolve grease and cold water so as not to damage the clothing), we greatly increase our chances of resolving that contradiction.

When resolving a physical contradiction, we strive to address the contradictory requirements in either space, time, or condition (a.k.a., relationship). For instance, can we separate the contradictory requirements of water temperature in space? Where do we want hot water? In the washing machine. Where do we want cold water? Also, in the washing machine. Since the location requirements for the hot and cold water are the same, it will not be easy to try to separate the contradictory requirements in space.

When do we want hot water? When washing the clothes. When do we want cold water? Also, when washing the clothes. As with separation in space, we have the same requirements for the hot and cold water at the same time. Once again, since the temporal requirements for the hot and cold water are the same, it will not be easy to try to separate the contradictory requirements in time.

This leaves us with separation in condition (or relation). Under what condition (or relationship) do we want hot water? In relation to the grease. Under what condition (or relationship) do we want cold water? In relation to the clothing. Now we have two different answers when testing for the separation of hot and cold water in condition (or relationship). How might we have hot water at the site of the grease but have cold water everywhere else (on the clothing)? The purpose of the hot water is simply to raise the energy level at the site of the grease. Might we be able to accomplish the same by adding a micro-wave generator to the washing machine that is tuned so that the micro-waves are only absorbed by the grease (and not the water or the clothing)? This particular solution may or may not work, but it is intriguing. The main take away from this example, though, is that a potential solution has been generated by capturing the contradictory requirements for both hot and cold water in clothes washing machines. By generating and pursuing several such solutions, we may discover the one that results in a breakthrough innovation.

A Wireless Network Case Study

Now that we understand the basics of contradiction analysis, let’s apply it to a case study in the wireless industry. Suppose that a wireless phone company needs a significant amount of equipment to improve the system’s coverage area, but the company also wants very little equipment because it is expensive.

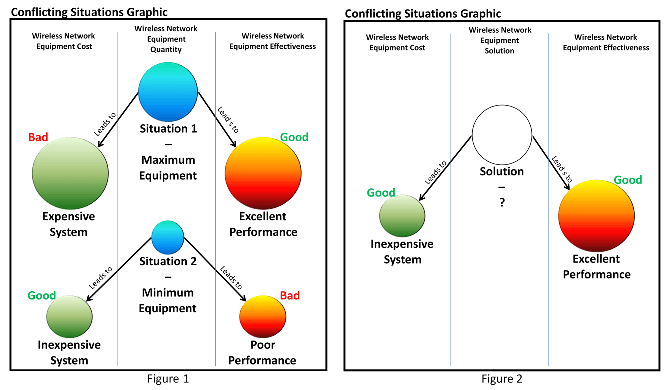

Generally speaking, there are two boundary conditions (existing at the opposite ends of a continuum) that define the range of available solutions to this problem within the restrictions set forth by the existing system design. In other words, based on how our fictitious wireless service provider’s technical systems are designed, there are two extremes defined by the current system limitations and therefore the solution can only exist somewhere between them. Figure 1 shows these two extremes.

- In situation one of Figure 1, the amount of wireless network equipment is at a maximum (large blue circle). This large amount of equipment drives two results: First, the cost of the system (large green circle on the left), which is very high, represents an undesirable situation. Second, the performance (or effectiveness) of the system (large orange circle on the right), which is excellent, represents a desirable situation.

- In situation two of Figure 1, the amount of wireless network equipment is at a minimum (small blue circle). This small amount of equipment drives two results: First, the cost of the system (small green circle on the left), which is very low, represents a desirable situation. Second, the performance (or effectiveness) of the system (small orange circle on the right), which is poor, represents an undesirable situation.

Therefore, the large amount of equipment needed for quality services is in conflict with the small amount of equipment needed for controlling costs. On the one hand the company wants a large amount of cell towers, repeaters, and switching circuits and on the other hand the company does not want to have to pay for any equipment at all. This represents a contradictory requirement that serves as a system limitation. So, the question is: how can the company spend very little on network equipment but have the system perform as if there is a lot of equipment in operation? In order to solve this problem with an innovative solution, it is necessary to resolve the limiting system contradiction.

The abstract model of such a solution is shown in Figure 2. In this diagram, the solution (which is not necessarily just based around equipment quantity) is the “unknown” solution state depicted as a white circle. The yet unknown solution must result in the best of both worlds as reflected in the two previously defined contradiction models (Figure 1). First, the solution should be relatively inexpensive (small green circle at the left in Figure 2), representing a good situation. Second, the solution should have a high level of performance (large orange circle at the right in Figure 2), representing a good situation. Any solution that simultaneously meets the inexpensive and high-performance requirements of the abstract solution model (Figure 2) will be an innovative solution. To resolve the contradictory requirements around the parameter of equipment quantity, we will need to resolve the contradictions.

How can the system simultaneously contain substantial equipment, so it can support the need for wireless services, and very little equipment, to help control costs?

- Where should there be substantial amount of network equipment to increase the coverage area? Where the cell phones need service.

- Where should there be a minimum amount of network equipment to reduce costs? Where there are no, or few, cell phones.

Since there are different answers to the separation in space questions, we may very well be able to separate the contradictory requirements in space. One idea is to design smart phones with repeater capabilities so that the collection of phones in the network are orchestrated to also act as the network itself. The higher the density of the phones, the better the bandwidth and coverage. While this may be a somewhat simplistic case study (driven by the article’s space limitations), it does bring to light a very real problem faced by the wireless service providers. Further, the considered solution space, though seemingly impossible when viewed through the lens of current mobile phone technology, does provide a solution vector that could possibly drive new technologies. Remember, it is also doubtful that the designers of early vacuum tube based computers would have ever imagined that in a mere 60 years most everyone on the planet would be carrying in their pocket a computational device with millions of times more capability.

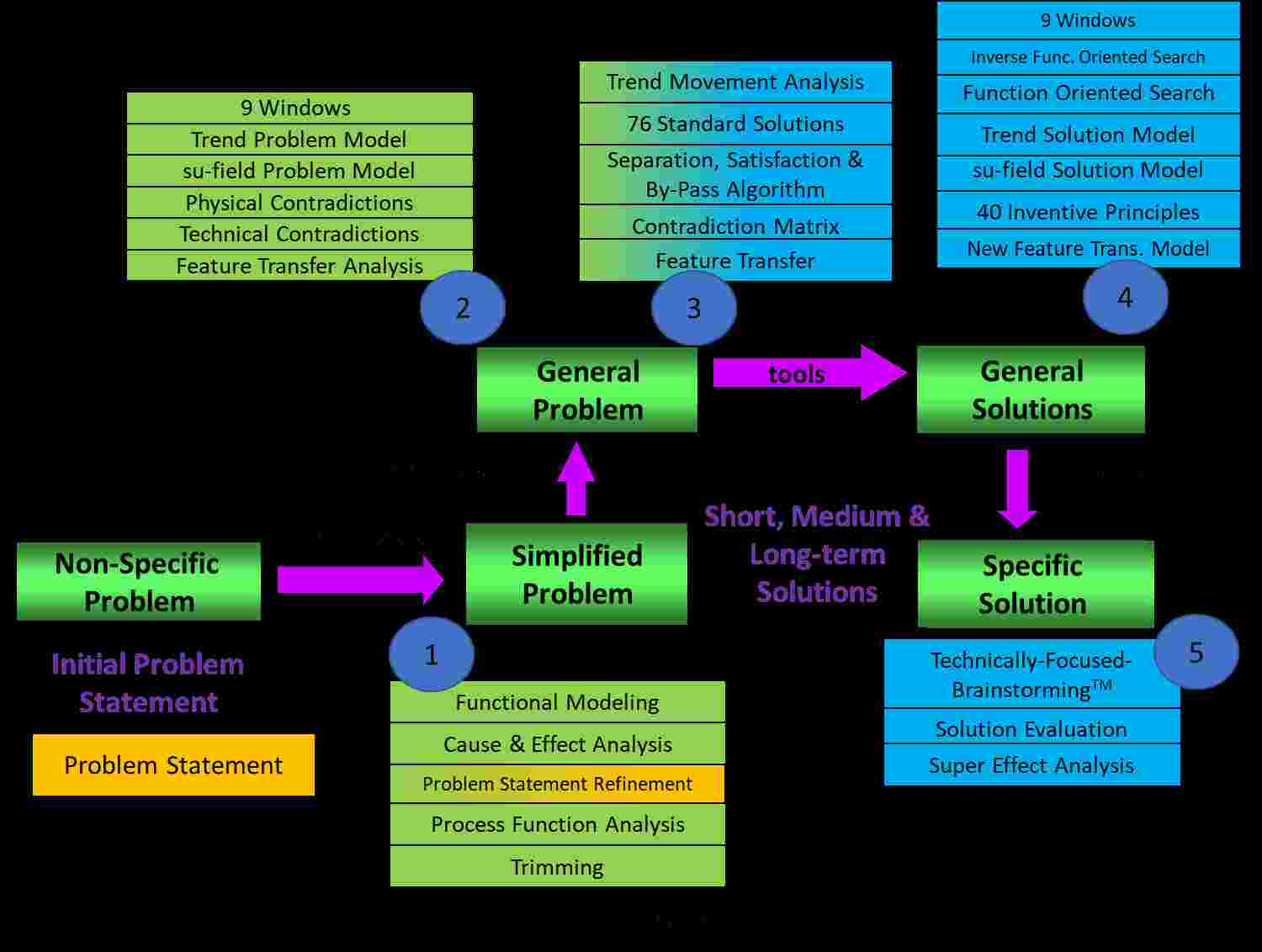

The Wider Systematic Innovation Toolkit

As shown in Figure 3, contradiction analysis is just one of the many techniques leveraged by TRIZ. Moreover, and also shown in Figure 3, the larger category of systematic innovation (SI) contains even more tools. A few of them are listed below. Though only a single problem modeling tool has been presented (i.e., contradiction modeling) in this article, TRIZ offers a host of solution generation tools (see Fig. 3).

Additional SI techniques Included in Step 1 of Figure 3:

- Functional Modeling: A graphical model of a function being performed. Function analysis deals with the entity components that are material objects and are related by way of an action (function) of one of the components on the other. Details what is happening within a complex engineering system.

- Cause and Effect Chains: A graphical model of the analyzed engineering system that reflects the inter-dependence of its disadvantages. Related directly to the associated functional model and details why things are happening within the engineering system.

- Process Function Analysis: A series of linked functional models that details an engineering process and allows the value ranking of all process functions (like Lean on steroids).

Additional TRIZ techniques included in Step 2-4 of Figure 3:

- (Step 2) Technical or Engineering Contradictions: An abstraction of a simplified problem and represents a situation in which an attempt to improve one parameter of an engineering system leads to the worsening of another parameter.

- (Step 3) Contradiction Matrix: A TRIZ tool that allows the identification of specific 40 Principles applicable to the technical contradiction under analysis.

- (Step 4) The 40 Inventive Principles: A problem solving tool that provides generalized recommendations for modifying a system to solve a problem formulated as an technical/engineering or physical contradiction (an inventive principle is an abstract model of the solution to the problem).

- (Steps 2 and 4) Su-field Problem and Solution Models: Symbolic model of a problem or solution formulated in terms of interactions between substances and fields (virtual, real, or improved).

- (Step 3) The 76 Standard Solutions: A set of solutions, in the form of substance-field (Su-field) models, to typical problems that are also expressed in the form of Su-field models.

When employed as an orchestrated set, the SI and TRIZ tools and methods can be used to decompose, abstract, and solve extremely complex and convoluted problems. I personally have used SI and TRIZ to help a national lab develop quantum computing R&D platforms, improve US Air Force satellite control systems and super structures, design ways for the US Army to stop speeding vehicles with little to no damage to the vehicles and no harm to their occupants, advance corn embryo breeding for a world-wide agribusiness, enhance diabetes medications for an international drug company, and improve the utilization rate of operating room suites for Presbyterian Hospitals of New Mexico, to name a few. My very first SI/TRIZ project at Intel Corp. saved the company $250M/year in damage losses to its micro-processor test platforms and an analysis of another 32 projects (executed by my Intel TRIZ students) showed a $1.3 billion impact to Intel’s bottom line. Oh, and guess what, SI/TRIZ is also used for business and organizational problem solving on a regular basis.

TRIZ is the only advanced problem solving methodology that utilizes solution generation engines based on a systematic study of the world-wide patent data base. Perhaps this is why SI/TRIZ is the most powerful problem solving and innovation engine on the planet. If your organization could benefit from a step function improvement in your problem solving and innovation capabilities, I highly recommend that you begin down the exciting and powerful TRIZ pathway. Eogogics offers both courses and consulting to help your organization become a power user of TRIZ. Give us a call!

Editor’s Note: David W. Conley, Eogogics Principal TRIZ faculty, is one of the TRIZ industry’s tier-one experts with International TRIZ Association’s (MATRIZ) Level 4 certification, 15 years as a TRIZ and innovation trainer and practitioner, eight years as the chair of Intel Corp’s world-wide innovation program, 35 years of engineering experience, and 27 years in manufacturing process improvement. David has served on the Executive Board and Certification Committee of the US-based Altshuller Institute for TRIZ Studies. He is the author and presenter of dozens of papers on Systematic Innovation and TRIZ.

Sorry, comments for this entry are closed at this time.